Counterfeiting is a growing threat that costs the world USD 500 billion a year, according to the US Chamber of Commerce. Because of this, the demand for anti-counterfeit security inks has surged, with the industry now estimated at over USD 3.3 billion.

To fight increasingly sophisticated counterfeit products, the security ink and pigment industries are racing to pioneer innovative anti-counterfeiting technology.

However, ink manufacturers face a delicate balancing act: creating intricate custom colors for customers, protecting their inks from replication, and ensuring compliance with stringent regulations — all while keeping the solutions affordable for their customers and end users.

Researchers Y.Pointel et al. from France believe colloidal suspensions of lanthanide-based coordination polymer molecular alloys (LnCPMA) may be the answer for anti-counterfeiting applications.

In particular, for quality anti-counterfeit taggant inks.

Let’s learn why.

Lanthanide-based molecular alloys are used as taggants but have a huge disadvantage

Lanthanide-based molecular alloys have been popular for decades. They offer remarkable luminescence and magnetism, which makes them very useful to:

- Develop lighting, LED displays, and optical sensors,

- Encapsulate and deliver drugs for targeted therapies,

- Act as contrast agents in optical imaging and

- Offer security as taggant inks for anti-counterfeiting, tamper evidence, and authentication purposes.

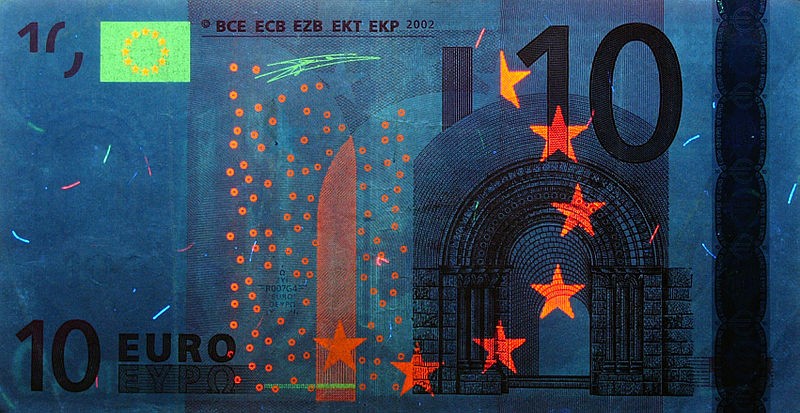

Most of these taggant inks are invisible to the naked eye, ensuring security while offering desirable optical properties that preserve the original look of a brand or document.

They can be highly customized for unique security measures and can be visible when exposed to UV light or infrared light. In many industries, they are considered mandatory anti-counterfeiting methods.

However, a significant challenge for ink manufacturers is that these molecules are not soluble. As a result, they are very difficult to use in their liquid state.

To overcome this hurdle, scientists often have to use workarounds like ultrasound or microwave-assisted irradiation or post-synthetic treatments like suspension in ionic liquids or poly-alcohols or encapsulating the coordination polymer (CP) with an organic polymer.

However, as researchers Y.Pointel et al. point out, these dissolution techniques have several inherent drawbacks.

Challenges with post-synthesis dissolution techniques

Challenges with using standard industry methods to dissolve lanthanide-based coordination polymers include:

- Uncontrolled purity: Inconsistent ink purity may risk non-compliance with regulations and result in a large amount of wasted product.

- Solvent toxicity: Commonly used ionic liquids have been shown to have varying levels of toxicity for humans who come in contact with them when ionic residues remain in the final product or leach into the environment.

- Added costs of the dissolution processes: Producing security inks is an expensive process, and the introduction of new regulations makes it harder to keep costs low while maintaining quality. Post-synthesis dissolution processes add a considerable cost burden.

- Inefficiency: Having to add several dissolution steps after synthesis is not only expensive but also inefficient.

Adding to these issues is that, when used for luminescent inkjet printing applications, blue, green, and red-emitting nanocrystals are stored in their solid state and, when mixed, are often not homogenous.

This property negatively impacts the physical properties and quality of the end product.

Homogeneity of nanometric grains in micropowders is crucial

Nanometric grain homogeneity in the LnCPMA micropowders is essential to ensure:

- Consistency of color,

- Purity of color,

- Excellent optical properties with high visual quality,

- Uniform light emissions for even illumination,

- Consistency and reliability in how LEDs or lasers perform and

- Quality control of the final product.

So, how do security ink manufacturers ensure high luminescence, a broad spectrum of tunable colors, excellent security, and maintain end-to-end quality while controlling costs?

Soluble lanthanide-based molecular alloys offer promise in taggant inks

Y.Pointel et al. report that LnCPMAs that are iso-structural to [Eu2(dcpa)3(H2O)]∞, where H2dcpa stands for 4,5-dichlorophthalic acid, demonstrate potential for use in anti-counterfeit taggant inks.

Benefits of soluble LnCPMAs

- Bright luminescence in both solid and liquid states,

- A broad range of highly tunable colors,

- More cost-effective processes versus standard ones,

- High stability, and

- Higher quality control due to highly homogenous nanometric grains in the LnCPMA micropowders.

Creating the soluble LnCPMA powders

- Powder X-ray diffraction,

- Electron dispersive spectroscopy (EDS) measurement and

- Optical and colorimetric measurements.

The researchers focused on end-to-end quality and efficiency with their lipidic nanoparticle (LNP) analysis; they measured particles in the colloidal suspension using a DLS particle size analyzer with an in situ and contactless remote optical head.

Having an in situ and contactless remote optical head for a particle size analyzer is helpful because it allows measurements to be taken without disturbing the sample, making it ideal for situations where sampling could modify the sample state, when measuring in limited spaces, and while dealing with valuable or hostile samples.

Final thoughts

- The anti-counterfeit security ink industry is in huge demand due to soaring counterfeiting activity.

- Ink manufacturers use lanthanide-based molecular alloys in anti-counterfeiting applications as taggants in security inks.

- However, a considerable challenge with common lanthanide-based molecular alloys is that they are not soluble, making it hard to control the physical properties and end quality of the product, costs, and efficiency of the entire process.

- Researchers from France believe that a colloidal suspension of lanthanide-based coordination polymer molecular alloys may be the answer to making highly luminescent taggant inks with tunable colors that meet regulations, improve efficiency, and cost-effectiveness.

- To achieve end-to-end quality and efficiency when making the LnCPMA, the scientists used a DLS particle size analyzer with an in situ and contactless remote optical head.

About VASCO-KIN™ Particle Size Analyzer

VASCO-KIN™ is a next-generation particle size analyzer with a time-resolved instrument that allows you to perform accurate kinetic analyses. Using the in situ and contactless remote head, you can measure your liposome and lipid nanoparticles where you prepare your samples; there’s no need to move or disturb them.

Using VASCO-KIN™, You can measure nanoparticle synthesis, agglomeration, or the stability of suspensions and perform nanoparticle synthesis monitoring in real time.

The instrument comes with a frequency-stabilized laser and artifact-free avalanche photodiode (APD) detector for high measurement accuracy and extremely low scattering samples.

VASCO-KIN™ also has a user-friendly software platform that gives you single and continuous measurement readings for all particle characterization data, including size distribution, scattered intensity, correlograms, and much more.

You may want to consider VASCO-KIN™ to measure nanoparticles in your research. Based on enhanced mathematical models, the DLS particle size analyzer offers high reliability of results and a 2D color map of particle size distribution over time — valuable insights to propel your research forward.

Want to learn how VASCO-KIN™ can help you achieve your results more efficiently?

Visit www.nanoexact.io to learn more.

Sources

- Counterfeit products cost the global economy over $500 billion a year. That’s why the private sector is partnering with U.S. Customs and Border protection to raise awareness nationwide to educate Americans about the dangers of counterfeits. (2022, August 11). Uschamber.com; U.S. Chamber of Commerce. https://www.uschamber.com/intellectual-property/back-to-school-business-and-law-enforcement-team-up-to-protect-students-parents-and-teachers-from-counterfeit-goods

- Security Inks Market size, share, growth analysis, by type, application — industry forecast 2023–2030. (n.d.). Skyquestt.com. Retrieved October 26, 2023, from https://www.skyquestt.com/report/security-inks-market

- Pointel, Y., Daiguebonne, C., Suffren, Y., Le Natur, F., Freslon, S., Calvez, G., Bernot, K., Jacob, D., & Guillou, O. (2021). Colloidal suspensions of highly luminescent lanthanide-based coordination polymer molecular alloys for ink-jet printing and tagging of technical liquids. Inorganic Chemistry Frontiers, 8(8), 2125–2135. https://doi.org/10.1039/d1qi00060h

- Valtchev, V., & Tosheva, L. (2013). Porous nanosized particles: Preparation, properties, and applications. Chemical Reviews, 113(8), 6734–6760. https://doi.org/10.1021/cr300439k

- Kuroda, K. (2022). A simple overview of toxicity of ionic liquids and designs of biocompatible ionic liquids. New Journal of Chemistry, 46(42), 20047–20052. https://doi.org/10.1039/d2nj02634a